Řízení procesu pevných částic v oběhové vodě (II) Regulace TSS prostřednictvím rozumného krmení!

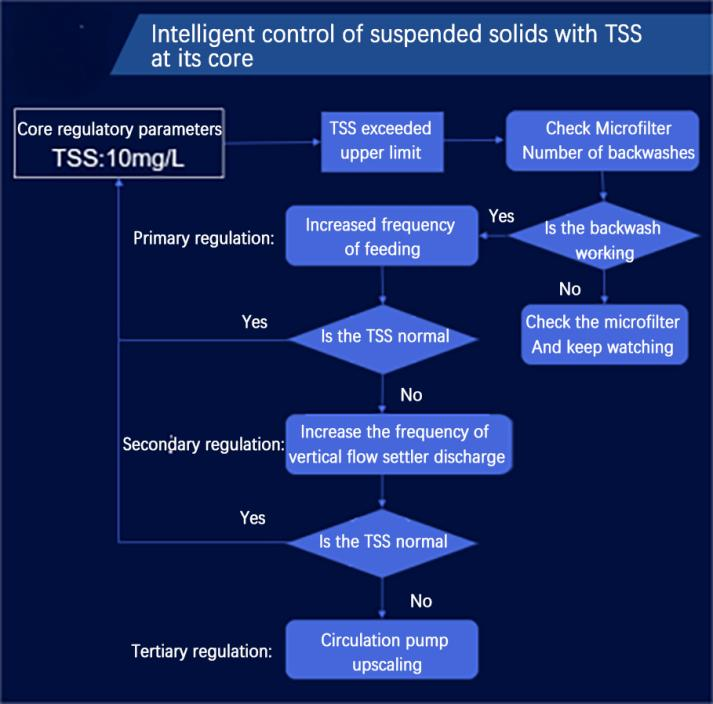

Model řízení procesu pevných částic v oběhové vodě

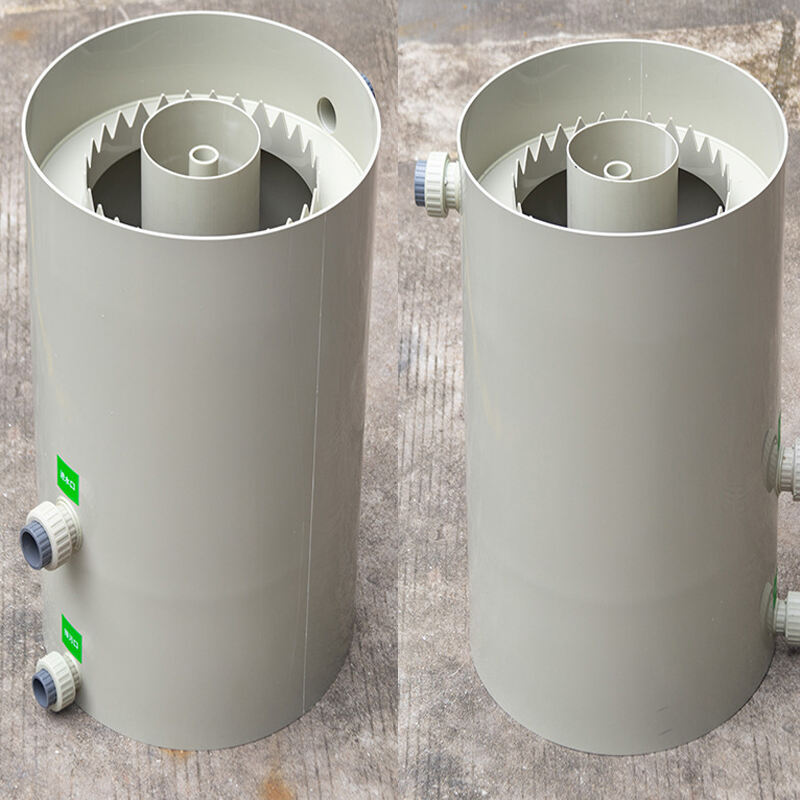

V systému recirkulační akvakultury je regulační model pro řízení pevných částic nástrojem používaným k optimalizaci kontroly závěsných pevných částic (TSS). Vytvořením modelu lze analyzovat a optimalizovat vznik, odstraňování a regulaci pevných částic za účelem zajištění stabilní kvality vody a efektivního provozu systému. Níže jsou uvedeny podrobné kroky a metody pro tvorbu a správu modelu.

(1). Cíle modelu

Koncentrace pevných částic TSS: 10mg/L

Optimalizujte účinnost odstranění: Upravte provozní parametry filtračního zařízení, abyste optimalizovali odstraňování tuhých částic. Vzorec pro výpočet účinnosti odstranění je:

ETSS=

ETSS: Účinnost odstranění (%)

TSSin: Koncentrace TSS na vstupu (mg/L): Namontujte senzor TSS na vstupu vody do mikrofiltračního stroje, abyste získali hodnotu

TSSout: Koncentrace TSS na výstupu (mg/L): Namontujte senzor TSS na vstupu vody do rybničního systému, abyste získali hodnotu

Snižte provozní náklady: Snižte energetickou náročnost a náklady na údržbu zařízení optimalizací provozních opatření.

Ve recirkulačním akvakulturním systému je koncentrace závěsných tuhých částic (TSS) úzce spojena s energetickou náročností systému. Optimalizací kontroly hladiny TSS lze efektivně snížit energetickou náročnost a zlepšit provozní účinnost systému.

(2). Metody kontroly – Rozumné krmení

Když index obsahu pevných znečišťujících částic přesáhne prostřednictvím monitorování TSS 10 mg/L, je nutné provést následující kroky k regulaci.

1. Přesné dávkování: Vypočítejte množství krmení, abyste předešli nadměrnému krmení a nadbytečnému krmivu.

2. Upravte strategii krmení: Podle druhu, velikosti, růstového stádia a podmínek chovaných organismů sestavte vědecký plán krmení a uplatněte vhodné metody krmení, například krmení v malých dávkách opakovaně, aby se snížilo množství zbylého krmiva vstupujícího do vodního prostředí a tvorba pevných částic.

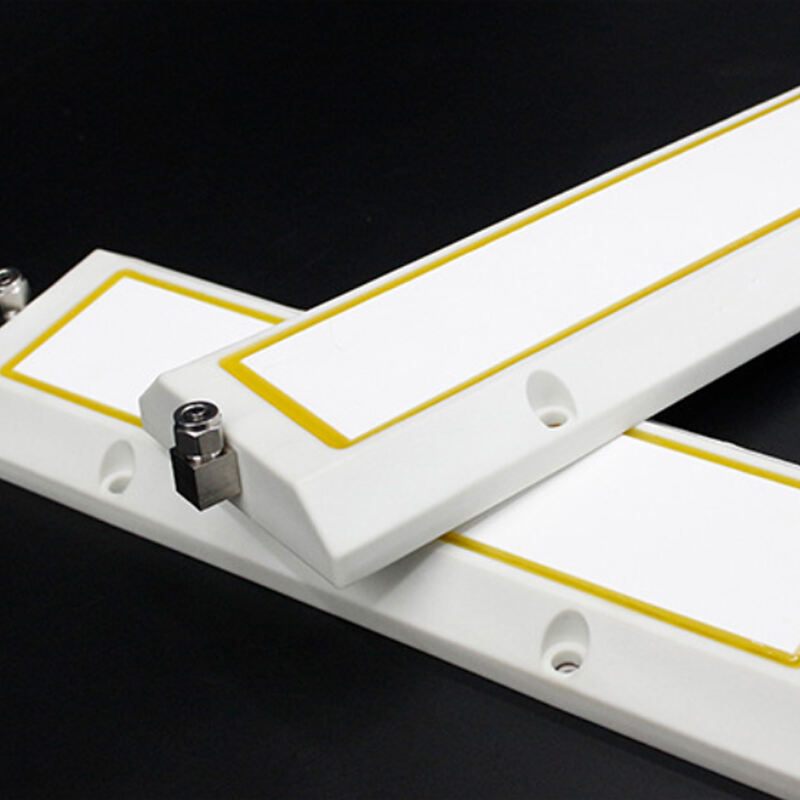

Doporučuje se použít krmící stroj pro krmení, který může nejen dosáhnout přesného dávkování, ale také krmit v menších dávkách a častěji. Naše společnost uvedla na trh inteligentní krmení pro recirkulační chov ryb. Chyba hmotnosti je díky vážícím senzorům nižší než 3 %. Krmení probíhá po celém procesu automaticky bez nutnosti manuálního zásahu. Nejenže nahrazuje ruční práci, ale také umožňuje snadno realizovat strategii krmení v menších dávkách a častěji.

3. Praktický případ

Recirkulace vody při chovu bílého kraba, objem vody 1000 metrů krychlových, hustota osazení 15 kg/metr krychlový, intenzita krmení 3 %. Účinnost odstraňování závěsných částic v systému recirkulace vody činí 60 %, voda je recirkulována každé 2 hodiny a používá se strategie krmení 4krát denně. Monitoring ukázal, že špičková hodnota TSS překročila 20,25 mg/L.

Po zjištění, že TSS překračuje normu, lze zvýšit frekvenci krmení, přičemž celkové denní množství krmení zůstává nezměněno, a lze upravit strategii krmení ze 4 denních porcí na 12 denních porcí.

Výpočet koncentrace TSS při 4 denních porcích krmení:

Objem vody: 1000 kubických metrů

Hustota chovu: 15 kg/m³

Míra krmení: 3 %

Účinnost odstranění suspendovaných částic v systému cirkulační vody: 80 %

Frekvence cirkulace: jednou za 2 hodiny, 12krát denně

Strategie krmení: 4krát denně

Krok 1: Výpočet celkové biomasy

Nejprve vypočtěte celkovou biomasu v akvakultivaci.

Celková biomasa = objem vody × hustota chovu = 1000 m3 × 15 kg/m3 = 15000 kg/den

Krok 2: Výpočet denní dávky krmiva

Podle dávkovacího režimu vypočtěte denní dávku krmiva.

Denní dávka krmiva = celková biomasa × dávkovací režim = 15000 kg × 3 % = 450 kg/den Denní dávka krmiva = celková biomasa × dávkovací režim = 15000 kg × 3 % = 450 kg/den

Jelikož je denně 4 krmení, dávka krmiva na jedno krmení je:

Dávka krmiva na jedno krmení = 450 kg/4 = 112,5 kg/krmení

Krok 3: Výpočet nárůstu TSS pro každý cyklus

Předpokládejme, že po nakrmění bude krmivo přeměněno na závěsné částice.

Po každém krmení dojde k následujícímu nárůstu TSS:

Nárůst TSS = dávka krmiva na jedno krmení = 112,5 kg

Krok 4: Výpočet odstranění TSS pro každý cyklus

Oběhový systém vody odstraní 80 % závěsných částic v každém cyklu. Proto je odstranění TSS po každém cyklu:

Odstranění TSS = aktuální TSS × 80 %

Krok 5: Simulace změn TSS během 24 hodin

Musíme simulovat změny TSS v cyklu každé 2 hodiny během 24 hodin. Během dne nastává 12 cyklů, tedy celkem 12 cyklů za 24 hodin.

Nastavte TSS na 0 kg.

Kroky pro každý cyklus:

Dávkování (jednou za 6 hodin, tj. jednou za 3 cykly)

Odstraňte 80 % TSS

Vypočtěte koncentraci TSS při 12 jídlech denně

Objem vody: 1000 kubických metrů

Hustota chovu: 15 kg/m³

Míra krmení: 3 %

Odstranění závěsných částic v oběhovém systému vody: 80%

Frekvence cirkulace: jednou za 2 hodiny, 12krát denně

Strategie krmení: 12 krmení denně

Krok 1: Výpočet celkové biomasy

Nejprve vypočtěte celkovou biomasu v akvakultivaci.

Celková biomasa = objem vody × hustota chovu = 1000 m3 × 15 kg/m3 = 15000 kg

Krok 2: Výpočet denní dávky krmiva

Vypočtěte denní množství krmiva na základě dávkování krmiva.

Denní dávka krmiva = celková biomasa × míra krmení = 15000 kg × 3% = 450 kg/den

Jelikož je denně 12 krmení, množství krmiva pro každé krmení je:

Množství krmiva na jedno krmení = 450 kg/12 = 37,5 kg/krmení

Krok 3: Výpočet nárůstu TSS pro každý cyklus

Předpokládejme, že po krmení bude krmivo přeměněno na závěsné částice. Po každém krmení dojde k nárůstu TSS:

Zvýšení TSS = dávkované množství na jednu porci = 37,5 kg

Krok 4: Výpočet odstranění TSS pro každý cyklus

Oběhový systém vody odstraní 80 % závěsných částic v každém cyklu. Proto je odstranění TSS po každém cyklu:

Odstranění TSS = aktuální TSS × 80 %

Krok 5: Simulace změn TSS během 24 hodin

Je třeba simulovat změny TSS po dobu 48 hodin s cyklem každé 2 hodiny. 12 cyklů denně, celkem 12 cyklů za 24 hodin.

Nastavte TSS na 0 kg.

Kroky každého cyklu:

Dávkování (jednou za 2 hodiny, tj. jednou za cyklus)

Odstraňte 80 % TSS

Z výše uvedené analýzy můžeme vidět, že:

4 krmení denně: Množství zaváděných částic prudce stoupne po krmení a poté postupně klesá. Maximální hodnota je vysoká (22,68 kg) a kolísání je velké.

12 krmných příjmů denně: Koncentrace zaváděných částic se stabilizuje na 9,37 mg/L

Závěr: Krmením malými porcemi v pravidelných intervalech lze snížit TSS a také energetickou náročnost zařízení.

Režim krmení 12krát denně efektivně snižuje špičkovou koncentraci zaváděných částic, omezuje kolísání kvality vody, snižuje zatížení i energetickou náročnost filtračních zařízení.

Krmný režim 4 krmy denně způsobí velké výkyvy v koncentraci závěsných částic a zvýší energetickou náročnost filtrů a vodních čerpadel.

Doporučené produkty

Aktuální novinky

-

Vánoční sleva přišla

2024-12-26

-

Je pravda, že chování ryb ve vysokooděnných plátněných nádržích je efektivnější než v obyčejných rybnících?

2024-12-16

-

Výhody galvanizované plátněné rybího nádrže

2024-10-14

-

Technologie vysoko hustotní chovu ryb, náklady rybího rybníka, plátněná rybí nádrž, plátněný rybník, vysoko hustotní chov ryb

2024-10-12

-

Proč volit vysoko hustotní akvakulturu proudící vodou

2023-11-20