Rheoli proses rhannau cryn yn y dŵr cylchredol (I): Golygyddion rheoli a chadeiriaeth y system orwedd!

Rheoli prosesau o gronynnau sylfaenol mewn cwchfa aquaculture

Mae'r gronynnau sydd yn ysgafnol mewn systemau pwll-dail adnewyddol yn cynnwys bwyta, gwaedd amlwg, flociau bacteriol a llithriad pysgod yn bennaf, sydd yn dod o'r bwyd cyfunol a roddir arnom, ac mae 25% o'r bwyd yn trosymud yn olhwyr yn y pen draw. Gall strategaethau bwyta a dulliau gwaredu anaddas ddod â chasgliad a threchu gronynnau sydd yn ysgafnol yn y system, sy'n cynyddu effaith droseddol ar iechyd y pysgod a chaerdydd y dŵr. Mae'r casglu gronynnau sydd yn ysgafnol yn achosi ymatebion stres yn y anifeiliaid a'u heintiff, yn effeithio ar anadlfa'r cwrdd a'u gostwng eu gwrthsefyllt i'r cleifion. Mae'r casglu gronynnau sydd yn ysgafnol hefyd yn gallu achosi blocio'r hoffathau pwll-dail. Mae trechu a mineralization o'r gronynnau sydd yn ysgafnol yn y system pwll-dail adnewyddol yn arwain at gynnydd yn nhâl amonia a nitrite yn y dŵr pwll-dail, yn cynyddu'r angen awyr biolegol, yn cynyddu'r llwyth ar y filter biolegol a'i weithred nitrification. Felly, mae gwaredu cyflym gronynnau sydd yn ysgafnol yn y system pwll-dail adnewyddol yn hanfodol i gynnal gweithrediad arferol y system lwcio, rhid dadfeithiant y dŵr a sicrhau tyfu arferol yr anifeiliaid a'u heintiff.

ⅰ. Beth yw rheoli prosesu gronynnau cryn gyda dwr cylchredol?

Mae'r rheoli prosesu gronynnau cryn mewn systemau pwll dŵr cylchredol yn cyfeirio at y broses o amcangyfrif, tynnu a rheoli gronynnau cryn sydd yn anhyborth (Total Suspended Solids, TSS) yn y corff dŵr trwy gyfres o fesurau technegol a rheoli mewn system pwll dŵr cylchredol er mwyn cadw ansawdd dŵr sefydlog, sicrhau iechyd bywydau pwll dŵr a gwella effeithloni gweithredol y system. Yn y system pwll dŵr cylchredol, mae rheoli prosesu gronynnau cryn yn ddolen allweddol i sicrhau gweithrediad effeithlon y system, cadw ansawdd dŵr sefydlog a sicrhau iechyd bywydau pwll dŵr. Mae rheoli gronynnau cryn mewn systemau pwll dŵr cylchredol yn cynnwys y rhannau canlynol:

(1). Objectives Rheoli

1. Cadw'r dŵr lân: Trwy reoli gronynnau solid, atalwch nhw rhag casglu yn y dŵr a chanllediadau ansicr, fel lleihau tryloywedd y corff dŵr a chynhyrchu amgylchedd byw da i seithiant organau pwnc. Rheoli TSS yn y corff dŵr o fewn ystod derbynadwy ar gyfer organau pwnc (fel arfer TSS yn cael ei reoli ar 10-30 mg/L)

2. Lleiha' sylwadau cleifion: Gall gronynnau solid gario pathogenau neu ddarparu lle i'r pathogenau ehosodi. Mae rheoli effeithiol o gronynnau solid yn helpu lleihau'r risg o organau pwnc cael eu heintio.

3. Gwellhau effeithloni'r system: atal blocio offer, estyn bywyd gwasanaeth offeryn a lleihau costau gweithredol.

(2). Cyswllt Rheoli

1. Bwydo rhesymol: Cyfrifwch faint y bwyd yn uniongyrchol i osgoi bwydo'n excesyddol a gadael gweddillion o fwyd. Yn ôl math, maint, cyfnod tyfu ac amgylchiadau bwydo'r seithiant, ffurfwch strategaeth bwydo wyddonol. Argymhellir gosod peiriant bwydo awtomatig a chymryd strategaeth bwydo wyddonol fel bwydo mewn swm bach a nifer o weithiau, i leihau gweddillion o fwyd sy'n mynd i mewn i'r corff dŵr a ffurfio gronynnau sylfaidd.

2. Optimeiddio dwysedd magwraeth: Yn ôl alluoedd y corff dŵr ar gyfer magwraeth a nodweddion tyfu'r seithiant, pennwch ddwysedd magwraeth yn rhesymol. Bydd dwysedd magwraeth ormodol yn arwain at gynyddiad yn y metabolitau byw a chynyddiad cyfatebol yn nifer y gronynnau sylfaidd a gynhyrchir. Felly, mae'n rhaid addasu dwysedd magwraeth yn barato i'ch atal rhag gorlanw.

(3). Orielu real-amser a rheoli proses

1. Orodwyta gweddilliant dŵr: Gosod mesurydd tryllydd i oredwyta crynodiad gronynnau solid, tryllydd a pharamedrau eraill yn y corff dŵr mewn amser real neu'n rheolaidd, yn ogystal â pharamedrau eraill cyswllt â gweddilliant dŵr megis ocsigen wedi'i ddodrefnu a gwerth pH, er mwyn deall newidion mewn gronynnau solid a gweddilliant dŵr.

2. Rheoli Trydanol: Yn seiliedig ar ddata'r oruchwyliaeth, defnyddir y system rheoli trydanol i addasu paramedrau gweithredu a prosesau trin ar gyfer offer cyswllt, megis addasu amser gweithredu a ffrwythlonedd yr hoffter, uchder aerio uned driniaeth biolegol, maint y cyfansoddwr cemegol sydd angen ei ychwanegu, ac ati, er mwyn cyrraedd rheoli uniongron gronynnau solid.

ⅱ. System oruchwyliaeth ar gyfer rheoli proses o gronynnau solid yn y dŵr cylchredol

Mae sefydlu system monitro ar gyfer reoli prosesau gronynnau sylfaenol yn y dŵr cylchredol yn gam bwysig tuag at weinyddu clyfar systemau brwydro â dŵr ailgylchu. Dim ond trwy orchymyn a rheoli crynodiad gronynnau sylfaenol sy'n anogaidd (TSS) yn y corff dŵr mewn amser real y gellir cynnal rheoli cywir i sicrhau ansawdd dŵr sefydlog a'i iechyd. Mae sefydlu system monitro ar gyfer reoli prosesau gronynnau sylfaenol yn y dŵr cylchredol yn gofyn am ddewis offer monitro priodol, gosod a dadfygio'r system, reoli a dadansoddi data, a'i integreiddio â'r system rheoli. Trwy orchymyn mewn amser real a rheoli clyfar, gellir rheoli crynodiad gronynnau sylfaenol sydd yn anogaidd yn y corff dŵr yn effeithiol i sicrhau gweithrediad effeithlon systemau brwydro â dŵr ailgylchu a'th tyfu iechydus organismau brwydro.

(1). Dewiswch offer monitro cywir

Mae angen defnyddio swnâr crysdedd sylfaenol TSS i fesur y gronynnau sydd wedi'u hatal yn y dŵr.

Egwyddor gweithredu: Mesur crysdedd y gronynnau sydd wedi'u hatal yn dŵr trwy ddefnyddio technoleg optegol neu donau sain.

Paramedrau Technegol:

Ystod fesur: 0-100 mg/L neu uwch.

Hyder: ±2% neu uwch.

Arwyddion allbwn: 4-20 mA, RS485, Modbus, ac ati.

(2). Gosodiad y swnâr

Lleoliad gosod:

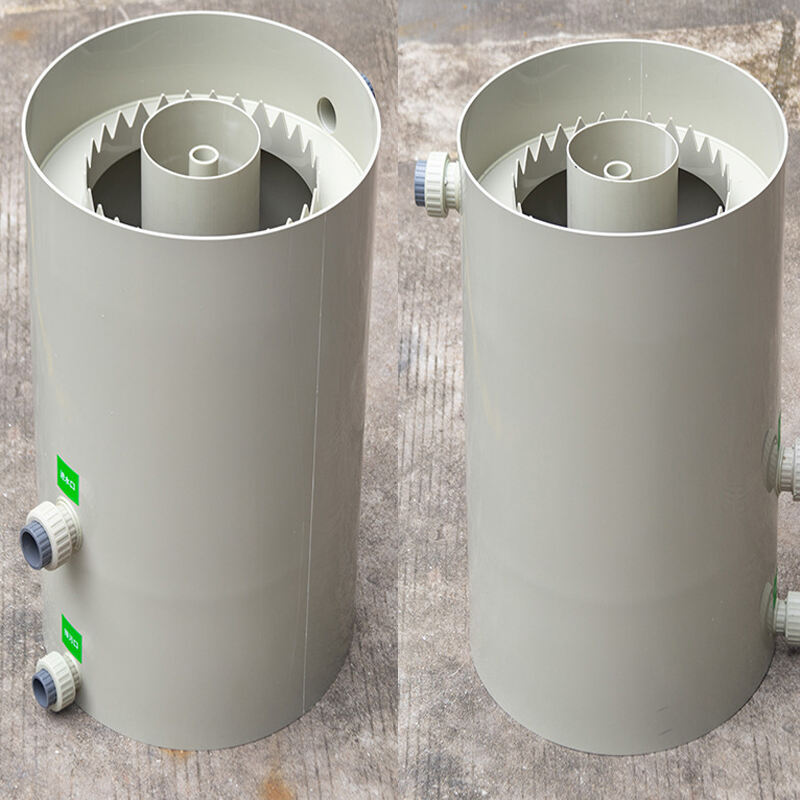

Pondmynedi: monitro crysdedd TSS yn y pondmynedi.

Mewnbwn a allbwn teclyn ffiltrowch: asesu effeithloni crefydd y teclyn ffiltrowch.

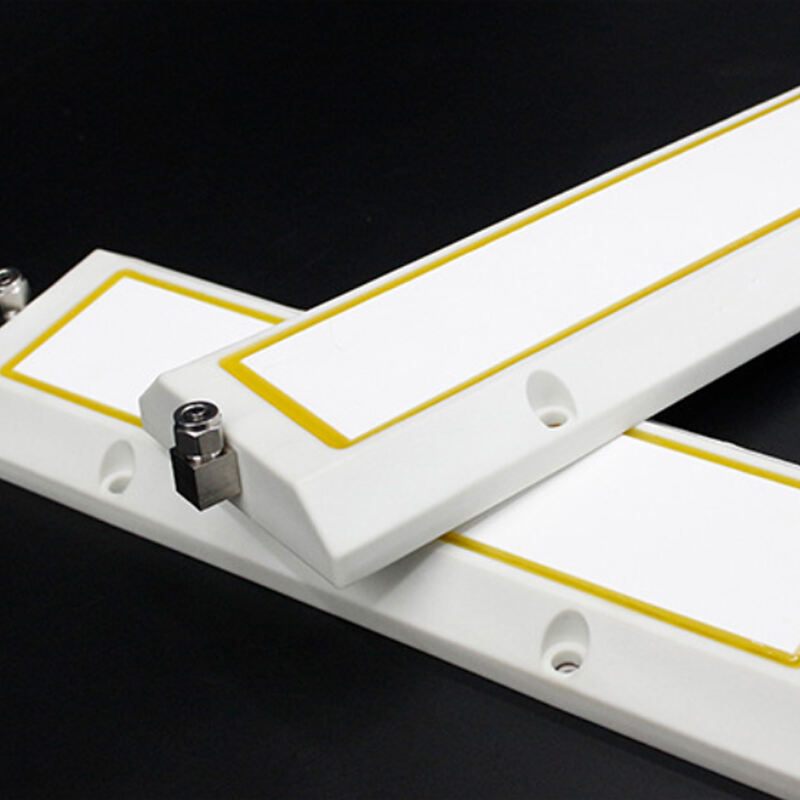

Dull gosod:

Dyw'r swnâr yn mynd o dan y dŵr: rhoi'r swnâr yn uniongyrchol o dan y corff dŵr.

Cynnyrchau Cyfrifol

Newyddion Poeth

-

Mae'r dasg ar gyfer Nadolig wedi dod

2024-12-26

-

A yw'n wir bod lladd pysgod mewn poethion pysgod ddamwain uchel-densiti yn fwy effeithiol na phoethion arferol?

2024-12-16

-

Pryderon galwadwy cymeradwy poblogaidd

2024-10-14

-

Technoleg lladd pysgod uchel-densiti, gost poeth pysgod, poeth pysgod ddamwain, pôb ddamwain, lladd pysgod uchel-densiti

2024-10-12

-

Pam ddylai un ddewis triwlithiaeth mawr-densiti dros dro

2023-11-20