Solid Particle Removal Process (III): Process Parameter Design and Practical Case Studies

(1)Design parameters for suspended particle removal process in circulating water system

1. Parameter design of vertical flow sedimentation tank

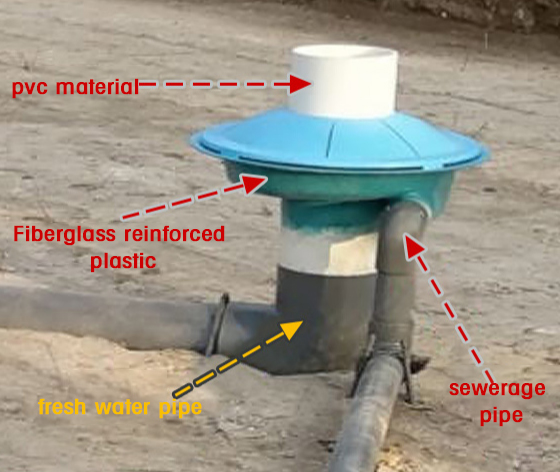

Cornell double-drain system has been widely used and has good practical results. In the aquaculture pond using Cornell double-drain system, 10%~25% of the water flows into the vertical flow sedimentation tank through the bottom drain pipe and most of the remaining water flows out through the side drain of the fish pond. The use of double-drain design greatly increases the ability of the bottom to drain and collect pollutants through the vertical slow flow. At this low flow rate, the concentration of particulate matter is increased by 10 times compared with the main flow measurement and discharge method.

The ratio of the flow rate through the vertical flow settler and the flow rate entering the side discharge can be calculated based on the cross-sectional area of the sewage pipe at the bottom of the fish toilet. Generally, the pipe entering the side discharge is 110, and the pipe entering the vertical flow settler is 50, so their cross-sectional area ratio is 5:1. That is to say, about 17% of the water flows into the vertical flow settler. Considering that the concentration of suspended particles entering the vertical flow settler is 10 times that of the concentration entering the side discharge. According to this calculation, the proportion of suspended particles treated by the vertical flow settler is about 70%. In specific use, the ratio of the pipe diameter entering the side discharge to the pipe diameter entering the vertical flow settler can be adjusted according to the specific aquaculture species and aquaculture density, so as to adjust the ratio of the flow entering the microfiltration machine and the vertical flow settler respectively.

The key indicator for determining vertical flow settlers is the hydraulic retention time. The hydraulic retention time refers to the average time that water stays in a vertical flow settler. Sufficient hydraulic retention time is one of the key factors to ensure that suspended particles are fully settled. It is related to the volume of the settler and the amount of water treated. In recirculating aquaculture, the hydraulic retention time of a vertical flow settler is recommended to be at least 30 seconds. If the hydraulic retention time is too short, the suspended particles may be taken out of the settler before they have time to settle; if it is too long, the size and cost of the equipment will increase.

In design, we usually design based on experience:

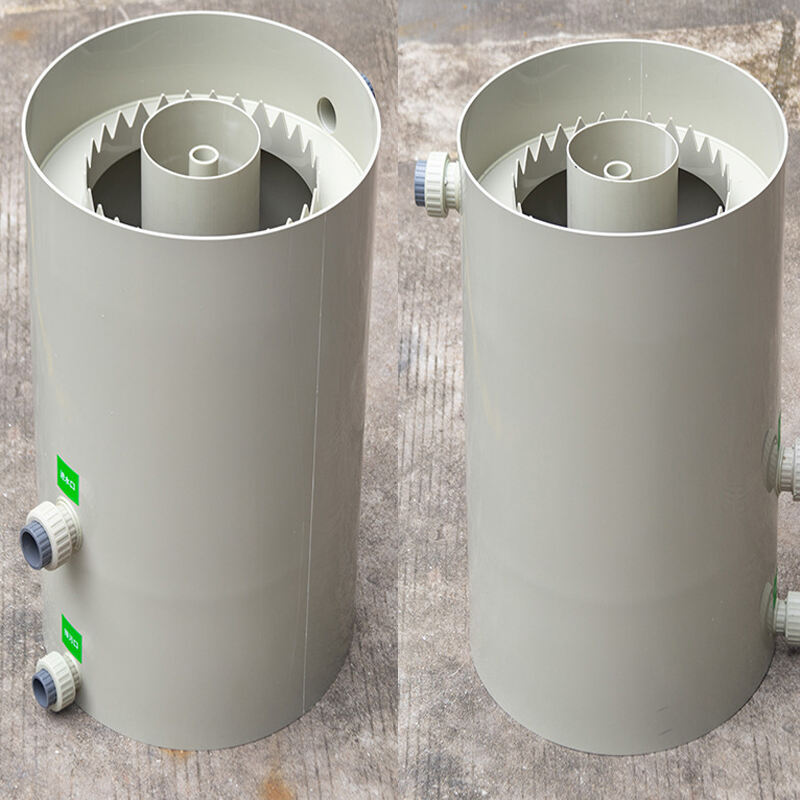

vertical flow sedimentation tank: A 6-meter breeding pond is equipped with a 600mm diameter vertical flow sedimentation tank, and an 8-meter breeding pond is equipped with an 800mm diameter vertical flow sedimentation tank.

Height of vertical flow sedimentation tank: 1 meter

Taper: 30 degrees

How to upgrade a vertical flow sedimentation tank into an intelligent vertical flow sedimentation tank?

Traditional vertical flow sedimentation tanks can only discharge sewage in the vertical flow sedimentation tank by pulling out the pipe. Generally, all the water in the vertical flow sedimentation tank will be discharged once the pipe is pulled out. Due to the large number of circulating water aquaculture ponds, manual work can generally only be done 1-2 times a day. However, the residual bait and feces in the vertical flow sedimentation tank will slowly disintegrate in half an hour, turning into suspended particles soluble in water, and then continue to float up, overflowing from the upper part of the vertical flow sedimentation tank into the microfiltration machine, increasing the burden on the microfiltration machine and protein separator.

Therefore, a smart sewage valve can be installed at the sewage pipe of the vertical flow sedimentation tank, and the sewage is discharged for a few seconds every hour, adopting a sewage discharge strategy of small amounts and multiple discharges. In this way, the residual bait and feces can be discharged in time, reducing the burden on the microfilter and protein separator. At the same time, the small amount and multiple discharges are very water-saving and greatly reduce the water change rate, which not only saves water but also saves energy consumption.

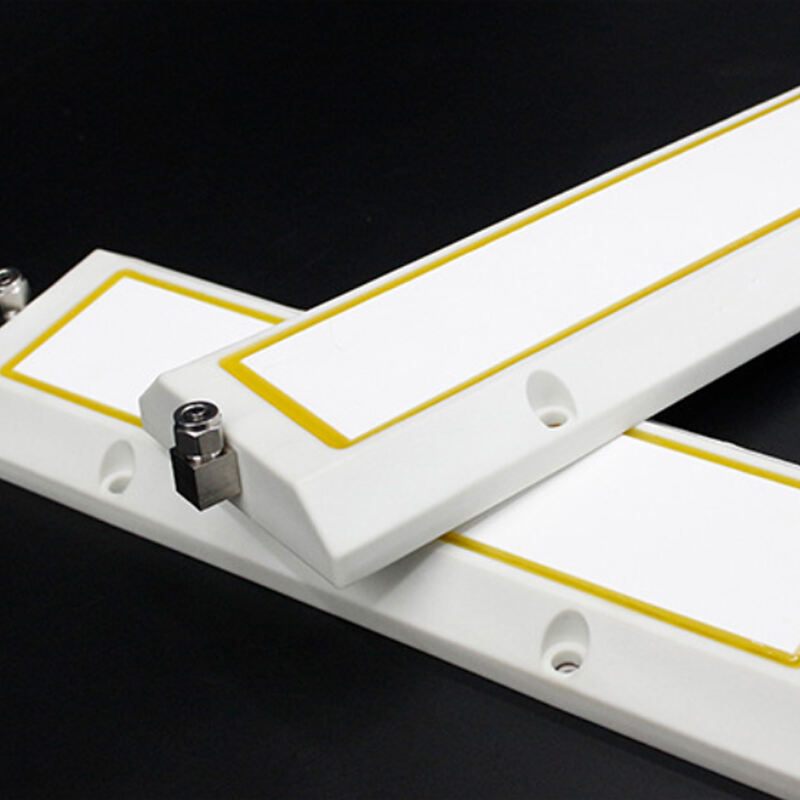

When choosing a sewage valve, you must choose an IP68 waterproof valve, otherwise the valve will easily rust and cause failure, which will bring unnecessary losses. If it is seawater aquaculture, it is recommended to choose UPVC material to prevent seawater corrosion.

Bangbang has launched a smart sewage valve on the market, which is specially designed for vertical flow sedimentation tanks. It is made of UPVC material and has IP68 waterproof performance. It also adopts the Internet of Things design and has Internet access function. It can be remotely controlled by mobile phone and batch plan control can be issued, which truly realizes unmanned operation. If the valve fails to close, a telephone alarm will be issued. This valve mini host has a modular design, one host drags four valves, and cloud networking is very convenient to install.

The traditional vertical flow sedimentation tank is truly upgraded to a smart vertical flow sedimentation tank by installing this device, realizing intelligent and unmanned operation, which not only improves the water quality but also saves water and electricity.

2. Parameter design of microfiltration machine

Microfilters are used to remove suspended solid particles of 30-100 microns. The processing capacity of a microfilter refers to the water flow capacity of the equipment. The size of the filter mesh determines the processing effect, and 200 mesh is generally sufficient. So how should we design the parameters of a microfilter?

First, let me introduce an engineer's experience data to facilitate practical operation:

Water flow = aquaculture water volume / circulation frequency * 1.2

1.2 is safety redundancy, and the circulation frequency refers to how many hours it takes to circulate once. The circulation frequency is generally determined according to different aquaculture species and biological carrying capacity. Taking 1000 cubic meters of circulating water for breeding sea bass as an example, it is best to set the circulation frequency to circulate once every 2 hours. Therefore, the water flow rate of the microfilter is: 1000/2*1.2=600 tons

In practice, you can install one 600-ton microfilter or two 300-ton microfilters. The advantage of installing two microfilters is that when one microfilter is out of service, the other one can still operate normally. However, the price of two small microfilters is greater than that of one microfilter.

3. Parameter design of protein skimmer

The protein skimmer is used to process suspended particles larger than 30 microns. The processing capacity of the protein skimmer refers to the amount of water flowing through it per hour. Each protein processor manufacturer's equipment will indicate the amount of water flowing through it per hour. For example, if a 1,000 cubic meter circulating water body is used to culture sea bass, the system's circulation volume is 600 tons per hour. Then you can choose a protein skimmer with a processing capacity of 600 tons per hour.

(2)、Calculate the circulation volume of the circulating water system

Above we gave an empirical rule of thumb for the circulation amount. Next we will give a rigorous derivation and calculation method.

First, we need to determine the amount of suspended solids (TSS) generated in the system. This can be calculated using the following formula:

RTSS = 0.25X maximum daily feed intake

Next, we calculated the system recirculation based on total suspended particulate matter using the following formula:

QTS S=

Where: QTSS is the calculated value of system circulation based on TSS, in m³/h;

TSSin is the target of circulating water TSS control;

TSSout is the target control concentration of TSS in the effluent of the aquaculture pond, in mg/L;

ETSS is the removal efficiency of TSS in the physical filtration process, expressed in %;

1000 is the mass conversion factor, converting mg to g.

三、Actual combat cases

A project of 1,000 cubic meters of circulating water for breeding sea bass is being constructed. The project design technical indicators are as follows:

Breeding density: 50kg/cubic meter

Daily feeding rate: 2%

The target removal rate of the suspended particle system is: 70%

The TSS control target of circulating water is: 10mg/L

According to the above indicators, we calculate the circulation volume of the circulating water system:

First, let's calculate the weight of suspended particulate matter produced every day:

RTSS = 0.25X maximum daily feeding amount = 50X1000X2 %X0.25= 250 kg/day.

According to the above analysis, 70% of the solid particles (mainly leftover bait and feces) will be discharged by the vertical flow sedimentation device, and only 30% of the suspended particles will enter the circulation system.

Based on this, calculate the circulation volume of the circulating water system:

QTSS = = 600.96 m³/h

This calculation result shows that in order to maintain the TSS concentration in the aquaculture pond below 10 mg/L, under the condition of 52% suspended particle removal rate, we need to design a circulation volume of about 600m³/h.

In actual operation, we can adjust the water circulation in the recirculating aquaculture system according to these parameters to ensure that the water quality meets the aquaculture needs. For example, if our TSS concentration exceeds the standard, there are two possibilities.

Microfiltration and protein skimmer equipment processing capacity is less than 52%

Vertical flow precipitator treatment capacity is less than 70%

Recommended Products

Hot News

-

The Christmas discount has arrived

2024-12-26

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20