Varför ska vi välja ett flödande vatten akvakultursystem?

Traditionell akvakultur står inför dubbla utmaningar från resurser och miljö: produktion av en ton fisk förbrukar 15 000 ton sötvatten, medan ackumulerad oätet foder orsakar övergödning av vatten. Stillastående vatten och intensiv odling leder till frekventa sjukdomsutbrott. Att sträva efter högkvalitativ, hållbar utveckling inom begränsade resurser är avgörande för framtida framsteg.

I. Vad är ett genomströmningsbaserat akvatursystem?

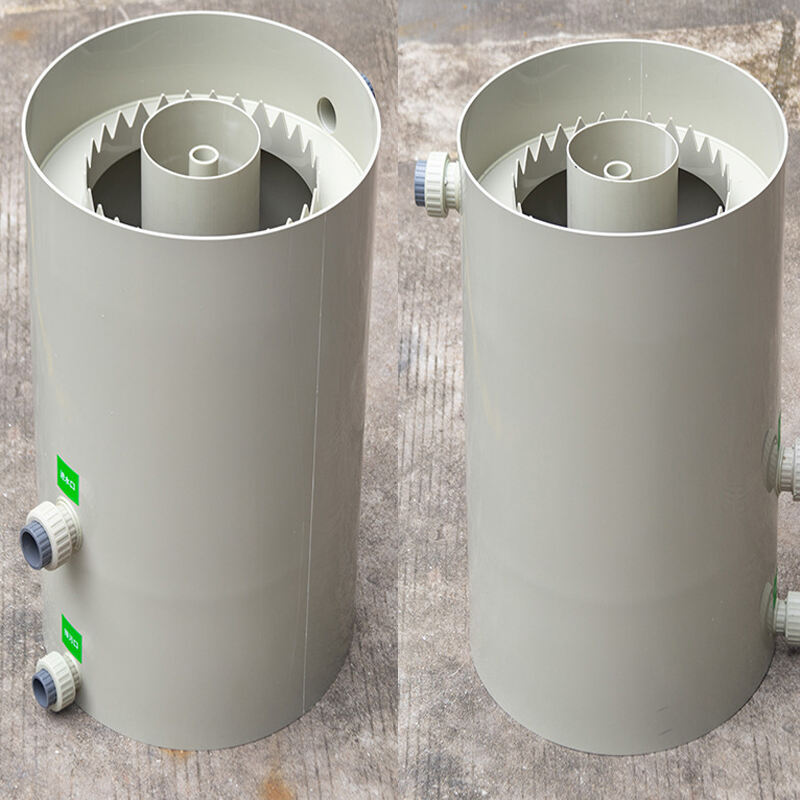

Ett genomströmningsbaserat akvakultursystem är en teknisk modell som möjliggör högdensitets intensivfödning av fisk genom konstgjord kontroll av vattenflödets riktning, hastighet och cirkulationsmönster. Dess kärnfunktion innebär att ta bort fiskavföring och återföra syre via vattenomsättning, samtidigt som vattenkvaliteten hålls stabil genom fysisk filtrering, biologisk rening (t.ex. mikrobiell nedbrytning) och kemisk behandling (t.ex. ozonsterilisering).

System med öppen flöde: Förlitar sig på kontinuerlig tillströmning från naturliga källor (t.ex. floder, bergskällor) med direkt utsläpp av använt vatten; lämpligt för terrassodling i bergsregioner.

Tekniska höjdpunkter:

Intelligent övervakning: Verifiering i realtid av löst syre, pH, ammoniakkväve etc., med automatiska varningar och justeringar av vattenkvalitet.

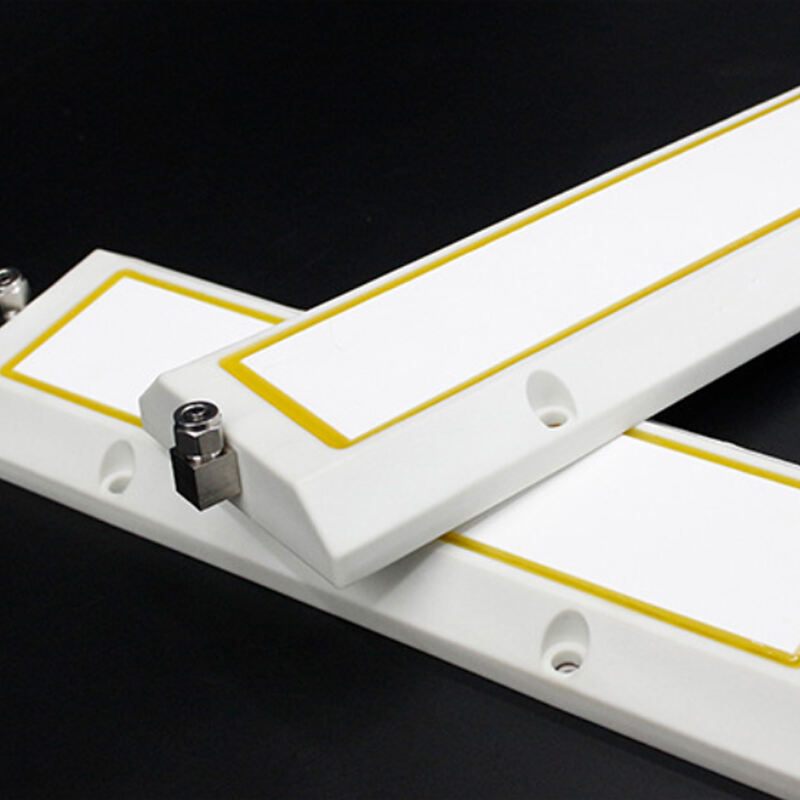

Segregerad avfallshantering: Bottenavrinning samlar upp fast avfall medan ytoverloppsrör avlägsnar oljeföroreningar, vilket minskar behovet av efterbehandling.

Lågkolsdioxiddesign: Funktioner som luftlyfthevar ersätter konventionella motorer, vilket ger över 30 % energibesparing.

II. Varför är ett flödesbaserat akvakultursystem nödvändigt?

Dess framväxt löser fyra stora problem inom traditionell odling:

Resurstryck: Konventionell dammodling förbrukar upp till 15 000 ton vatten per ton producerad fisk, medan återcirkulerande system minskar detta till under 100 ton.

Miljöförorening: Omatad foder och avföring orsakar näringsämnesförsurning av vatten.

Ofta sjukdomsutbrott: Högdensitetsodling i stillastående vatten är benägen att leda till epidemiutbrott; flödessystem minskar riskerna genom UV- och ozondesinfektion.

Markbegränsningar: Urbanisering minskar odlingsytor; vertikala flödesrännor (t.ex. höghusodlingsverkstäder) ökar produktionen per ytenhet tiofalt.

III. Global marknadsandel och regionala egenskaper

Baserat på data om akvakulturs marknadstorlek (global total 2022: 1,4148 biljoner CNY) och analys av teknikapplikation:

Asien (dominant marknad, 65 % andel): Kina utgör kärndriften, där genomströmningsodling står för 44 % av den totala akvatiska produktionen (2024). Hainans frihandelszon utvecklar djuphavskäfigar med vågmotstånd; Zhejiang främjar modellen "löpbandsfisk" (IPRS), vilket minskar karpfödningens cykel med 30 %¹².

Amerikas (20 % andel): Mississippi dominerar i måltidsfiskodling med storskaliga IPRS-system, som omvandlar avfall till gödsel via automatiska suganordningar⁵.

Europa (12 % andel): Underkastat stränga ekologiska standarder använder nederländska smarta växthus för räkor slutna RAS-system integrerade med solcellsel, vilket minskar energiberoendet med 30 %.

Afrika/Mellanöstern (3 % andel): I ett tidigt skede men mycket innovativt kombinerar Saudiarabien avsaltning med solenergidrivna recirkulationssystem, medan Israel uppnår fabriksskalig stödfiskodling i torra regioner.

IV. Analys av fyra kärnfördelar:

1. Ekologisk hållbarhet:

Vattenbesparing överstigande 90 %, med utgående avloppsvatten som uppfyller utsläppskrav eller återvinns för jordbruksbevattning.

Minskad antibiotikaanvändning, vilket resulterar i 'noll läkemedelsrester' i odling av rödfläckig havsabborre i Sanya, Hainan.

2. Betydande ekonomiska fördelar:

Ökad produktion per ytenhet: Fabriksodlad havsabborre i Xinjiang producerar 5 ton årligen per tank (80 m³), en åttagångsförlängning jämfört med traditionella dammar.

Kostnadsoptimering: Automatiserade utfodrings- och avfallssystem minskar arbetskostnader med 30 %.

3. Förbättrad kvalitet och säkerhet:

Konstant vattenflöde främjar fiskens rörelse, vilket ger fastare kött (t.ex. bergsöring från Xiuning säljs till en premie på 50 % per jin).

Fullständigt kontrollerade miljöer förhindrar förorening med tungmetaller.

4. Intelligenta och intensiva driftsystem:

IoT-hantering: 120 system i Ningde, Fujian överför 8 miljoner datapunkter årligen med en felfrekvens på <0,4 %.

modellen för 'flervåningsakvakultur': Högproduktiv odling av räkor i Fengjiawan Industrial Park i Wenchang ökar markanvändningseffektiviteten med 300 %.

V. Framtida trender och viktiga utvecklingsriktningar Tekniska utvecklingsvägar:

Utvidgning till djuphav: Wanning, Hainan, utvecklar stormbeständiga burar för djuphavsodling av stora gyllene spiggor;

Genombrudd inom avelschip: Molekylär avel skapar sjukdomsresistenta stammar, såsom genetiskt märkta Litopenaeus vannamei-räkor;

Integration och innovation inom tertiärnäringen: Modellen med 'turism kring forntida fiskdamm + matupplevelse' i Xiuning County, Anhui, ökar böndernas inkomster med 30 %.

Flödesdrivna akvakultursystem utgör en omedelbart förestående industriell revolution för traditionell fiskodling. Detta teknologiskt förstärkta tillvägagångssätt omvandlar fiskebruk från väderberoende till hydrologinformationsstyrda operationer, vilket utgör en utsökt fusion av hydrodynamik och ekologisk ingenjörskonst. Från bergsströmmar till djuphav, från tradition till innovation, gör detta tillvägagångssätt det möjligt för odlingar att uppnå mer effektiv och hållbar akvakultur med ekonomisk avkastning, samtidigt som konsumenter erbjuds högkvalitativa och säkra fiskprodukter.

Det strömmande vattnet talar inte, men framtiden är redan här. Flödesdrivna akvakultursystem har blivit huvudmodellen inom odling. Med kontinuerlig utveckling kommer de utan tvivel att bli den mest fördelaktiga supporten för fiskodlare!

Rekommenderade Produkter

Senaste Nytt

-

Julrabattarna har kommit

2024-12-26

-

Stämmer det att att odla fisk i högdensitetsaqua tankar av tyg är mer effektivt än vanliga dammar?

2024-12-16

-

Fördelar med galvaniserade tygdammar för fisk

2024-10-14

-

Högdensitetsfiskodlingsteknik, fiskdammkostnad, tygdamma, tygdamm, högdensitetsfiskodling

2024-10-12

-

Varför välja strömmande vatten högtdensitetsakvakultur

2023-11-20