Introduction to the structure and function of intelligent filtering drum machine!

Intelligent filtering drum machine

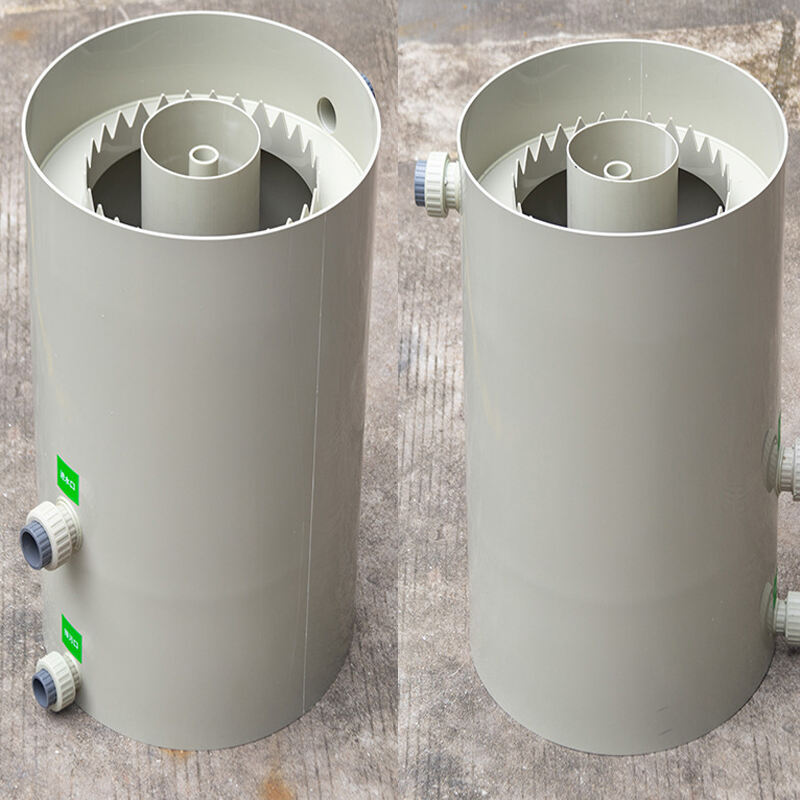

The filtering drum is the most important equipment in recirculating aquaculture and is also the equipment that is most prone to failure in daily use. Once a filtering drum fails, it will bring huge risks. With the rapid development of Internet of Things technology and sensor technology, the emergence of intelligent filtering drum has solved the pain points in the use of filtering drum. Next, taking the intelligent filtering drum launched by wolize as an example, I will give you a detailed introduction to the structure and characteristics of the intelligent filtering drum.

1. The structure of intelligent filtering drum machine

The mechanical structure of the intelligent filtering drum is the same as that of the traditional drum filtering drum. On this basis, the intelligent filtering drum has added three parts: a variety of sensors, an IoT smart control terminal, and control software.

1. Sensor

1) Turbidity/Suspended Solids (TSS) Sensor

Turbidity/suspended solids (TSS) is an important indicator to measure the amount of suspended particles in water. The filtration effect of the filtering drum machine can be monitored in real time by using an online turbidity/suspended solids (TSS) sensor. Generally speaking, the turbidity of water should be significantly reduced after being filtered through a filtering drum machine. For example, in unfiltered recirculating aquaculture water, the turbidity may reach tens or even hundreds of NTU (nephelometric turbidity units), while after effective filtration, the turbidity should ideally be reduced to below 10 NTU. If the turbidity continues to rise, it indicates that the filtering drum may be malfunctioning.

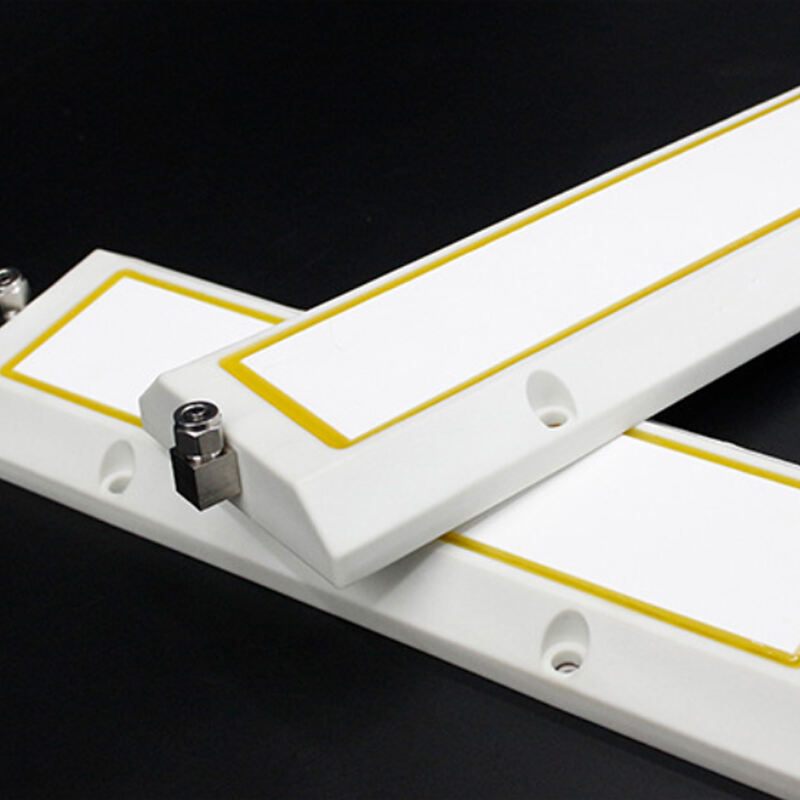

2) Digital liquid level sensor

The liquid level sensor is the core component of the filtering drum machine's back washing system. If the liquid level sensor fails, the back washing system will be paralyzed. Traditional filtering drum machines use float-type liquid level switches that cost more than a dozen yuan. This type of switch often has problems such as the float getting stuck and the circuit being short-circuited, and the failure rate is very high. The intelligent filtering drum machine launched by wolize uses a digital pressure-sensitive liquid level sensor. The digital sensor can understand the height of the liquid level in the filtering drum machine's drum in real time, and can also set the back washing height arbitrarily. The back washing liquid level can be set according to different breeding stages, saving water and electricity.

3) Current sensor

The drive system of the filtering drum is also a component that is prone to failure. By installing a current sensor, the operating status of the filtering drum drum motor and backwash water pump can be monitored in real time. When the equipment fails, a telephone alarm will be issued in time to avoid aquaculture accidents caused by filtering drum failure.

Current sensors can also obtain energy consumption data of equipment through current monitoring, and help users manage energy consumption through software system analysis.

2. IoT smart control terminal

The IoT intelligent control terminal is responsible for data collection, uploading and local execution.

First, the IoT smart control terminal is responsible for uploading the data collected by the sensor to the cloud computing and analysis center. The computing and analysis center uses algorithms to determine the operating status of the equipment.

If an abnormality is found, the cloud computing and analysis center will issue a work instruction to the IoT smart control terminal for local task execution. For example, if the cloud finds that the filter screen of the filtering drum is clogged through an algorithm, the cloud computing and analysis center will issue a back washing instruction. After receiving the instruction, the physical network smart control terminal will control the back washing mechanism of the filtering drum to automatically backwash. If the automatic back washing effect reaches the predetermined standard, the filtering drum will resume normal operation. If the filtering drum still fails to meet the standard after back washing, a telephone alarm will be issued.

3. Software control system

The software control system of the intelligent filtering drum consists of a mobile phone APP, PC software, a smart large screen control system and a cloud computing and analysis center. Users can remotely operate the filtering drum through the mobile phone software and can also monitor the operating status of the filtering drum in real time through the software. The cloud computing and analysis center is responsible for data storage, calculation and analysis. When problems are found, they will be solved in time or the alarm will be called.

2. Functions of intelligent filtering drum machine

1. Real-time monitoring of the operating status of the filtering drum machine

The filtering drum can monitor the operating status of the filtering drum in real time through sensors to determine the operating effect of the filtering drum. For example:

The turbidity index can be used to monitor the filtering effect of the filtering drum machine.

The back washing effect and back washing frequency of the filtering drum can be monitored by digital sensors.

The operating performance and energy consumption data of the drive system can be monitored through the current system.

2. Timely detection of filtering drum machine failure

The intelligent filtering drum uses algorithms to comprehensively analyze the data uploaded by each sensor, which can timely detect the failure of the filtering drum and give a comprehensive solution. The intelligent filtering drum launched by wolize can timely detect the following problems through data analysis and give treatment suggestions:

filtering drum filter is clogged

filtering drum screen damaged

3. Intelligent anti-cleaning function

The back washing liquid level of traditional filtering drums is fixed. Since a digital liquid level sensor is installed, the back washing liquid level can be set arbitrarily. For example, in the early stage of aquaculture, when the amount of feed is low and the water quality is good, the back washing liquid level can be set lower. This can reduce the height of the liquid level in the drum. When the drum rotates during back washing, the water level is lower and the load is lower during rotation, which not only saves electricity but also provides good protection for the filtering drum bearings. For another example, different aquaculture species have different requirements for water quality, so the back washing water level can be intelligently adjusted according to the aquaculture species.

3. Using the intelligent filtering drum machine as the core to realize multi-device linkage and intelligently adjust water quality

1. Link with the intelligent baiting machine to reduce organic load

The generation of suspended solids in recirculating aquaculture is caused by feeding. Every kilogram of feed put into the aquaculture pond will produce 0.25kg of suspended solids. When the intelligent filtering drum machine finds that the filtration effect has decreased through the turbidity sensor, it can link the intelligent feeding machine to change the feeding strategy, increase the feeding frequency and reduce the organic load of the water body after feeding.

2. Increase the circulation frequency of the circulation pump

When the intelligent filtering drum machine finds that the filtering effect is reduced through the turbidity sensor, the number of back washing times increases. The circulation frequency of the circulation pump can be increased. The increase in the circulation frequency is conducive to improving the water filtering effect. When the turbidity returns to normal, the frequency of the circulation pump is reduced to normal.

3. Increase the frequency of water changes

The intelligent filtering drum machine can also increase the frequency of sewage discharge when it finds that the filtering effect decreases and the number of back washing times increases through the turbidity sensor. Use a small amount of sewage discharge method to discharge sewage in time. For example, use the wolize intelligent sewage valve to discharge sewage once an hour, and each time for a few seconds.

The filtering drum is the core of the circulating water system. Taking the filtering drum as the leading factor and realizing the intelligent linkage of multiple devices, it can greatly improve the circulating water treatment effect, improve the water quality and effective biological load. With the same investment, the breeding density can be higher and the water quality can be better.

Recommended Products

Hot News

-

The Christmas discount has arrived

2024-12-26

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20