Design process of circulating water filtering drum machine (I) Structure and working principle of filtering drum machine!

The filtering drum in the recirculating aquaculture system is an important water treatment equipment, and its main function is to remove suspended solids in the water, including feed residues, fish feces, and biological bacterial masses. There are two main types of filtering drums: drum type and crawler type.

Drum filtering drum:

Filtration is performed using a rotating stainless steel drum with a dense 316L stainless steel screen attached to it, which is driven by a motor through gears.

Crawler type filtering drum:

By controlling the mesh size of the filter cloth, suspended particles with a diameter larger than the corresponding specification can be effectively removed from the water. By filtering on one side, with a built-in backwash device, and then by designing multiple sewage tanks and sewage outlets, secondary pollution can be effectively avoided.

After years of practice, rotary drum filtering drum has gradually become the mainstream of factory-scale recirculating aquaculture due to its compact structure, small footprint, good filtration effect, low operating cost and easy maintenance.

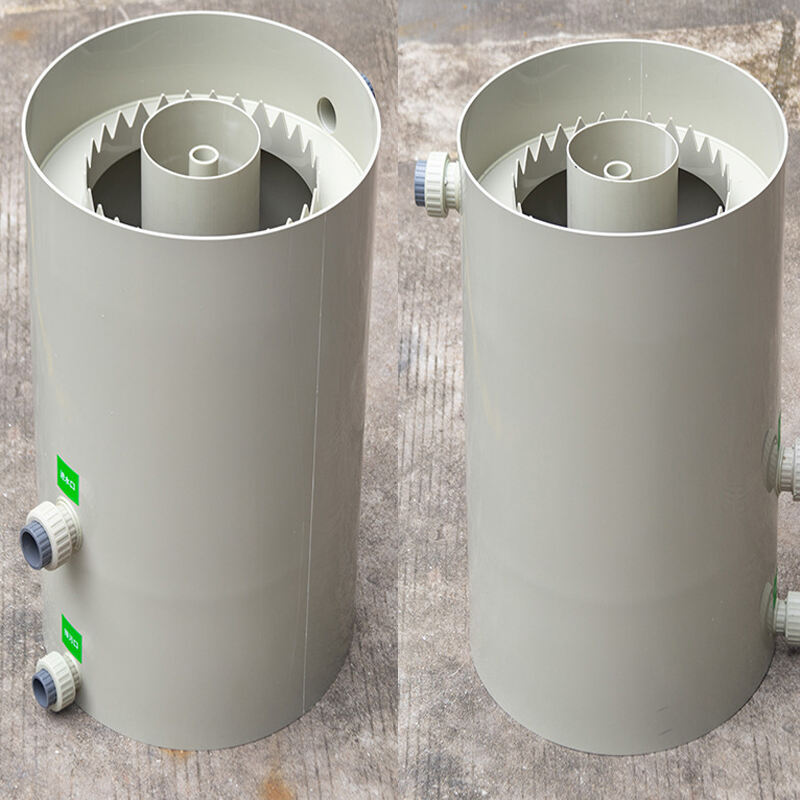

The structure and working principle of rotary drum filtering drum

The rotary drum filtering drum uses a rotating drum to filter. The outside of the drum is covered with a dense mesh and driven by a motor. A pump is installed outside the filtering drum. The filtered clean water is pumped away by the pump, while the dirt is left on the mesh and washed away by back washing.

1. The basic structure of the rotary drum filtering drum

The drum filtering drum is mainly composed of a horizontal drum, a filter screen, a driving device, a water inlet system, a water outlet system, a sewage system, a backwash system, and a control cabinet.

1. Roller:

This is the core component of the rotary drum filtering drum. It is generally a horizontally placed cylindrical structure consisting of a metal frame with a supporting mesh and a working mesh woven from stainless steel wire wrapped around the outside. The mesh size is usually between 60-250 meshes. Different mesh specifications can be selected according to actual needs to achieve the corresponding filtering accuracy.

2. Driving device:

It is composed of a motor and gears. The motor drives the drum to rotate through the gears. The general speed is 1-3r/min. Too fast a speed may cause large particles to break into tiny particles and pass through the filter, reducing the filtering effect.

3. Water inlet system:

It includes water inlet pipe and overflow weir water distributor, etc. The water inlet pipe introduces the aquaculture wastewater to be filtered into the filtering drum machine. After the wastewater enters the overflow weir water distributor, it can be evenly distributed on the filter cartridge filter screen rotating in the opposite direction after a short period of steady flow, so as to achieve better filtering effect.

4. Water outlet system:

It is mainly the water outlet pipe. The clean water filtered by the filter is discharged from the filtering drum machine through the water outlet pipe and enters the next water treatment link.

5. Sewage system:

It consists of a sewage collection tank and a sewage discharge pipe. The solid dirt intercepted by the filter screen will be collected in the sewage collection tank during the rotation of the drum, and then discharged from the filtering drum through the sewage discharge pipe.

6. Backwash system:

It consists of a back washing water pump, a back washing pressure nozzle, a liquid level sensor, a back washing pipe, etc. When the filter is clogged to a certain extent, the water level controller senses the water level change, starts the back washing water pump, and high-pressure water rushes to the filter through the nozzle, flushing the dirt attached to the filter into the sewage collection tank, thereby realizing automatic cleaning of the filter and ensuring the filtering effect.

7. Control chassis:

The control box is the brain of the filtering drum machine. The traditional control box can only perform localized control, and the parameter settings are complicated and inconvenient to operate. When the equipment fails, there is no telephone remote alarm system, which increases the risk of breeding. With the rapid development of the Internet of Things and sensor technology, intelligent filtering drum machines have appeared on the market. For example, the intelligent filtering drum machine launched by wolize can not only monitor the operation of the filtering drum machine in real time through a mobile phone, but also detect faults such as filter blockage, filter damage or back washing abnormalities in time through the use of a variety of sensors. After the fault is discovered, the relevant personnel can be informed by telephone alarm, which greatly reduces the failure rate of the filtering drum machine and reduces the risk of breeding.

2. Working principle of rotary drum filtering drum:

The working principle of the filtering drum mainly consists of two parts: filtration and back washing:

1. Filter:

The sewage enters the equipment through the feed port of the filtering drum and passes through the microporous surface of the filter. The commonly used micropore size is usually around 200 meshes, which can effectively intercept suspended solid particles and colloidal particles.

2. Anti-cleaning:

As the filtration time increases, the surface of the microporous filter membrane will gradually be blocked by solid particles and colloidal particles, reducing the filtration efficiency. In order to maintain the normal operation of the filtering drum machine, the microporous filter membrane needs to be cleaned, and the cleaning process is usually carried out by back washing.

Recommended Products

Hot News

-

The Christmas discount has arrived

2024-12-26

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20