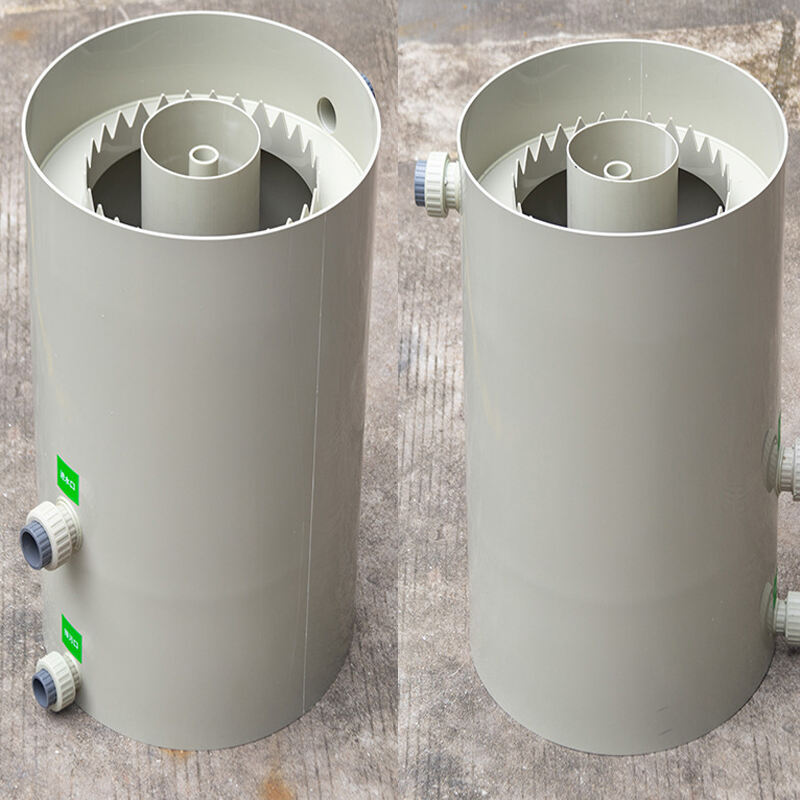

Maintenance and daily maintenance of circulating aquaculture filtering drum machine!

Daily maintenance of filtering drum machine

Daily maintenance of the circulating aquaculture filtering drum machine is essential for its normal operation and extended service life. The following are some common maintenance methods:

1. Filter cleaning:

The filter is the core component of the filtering drum and is easily clogged by impurities in the water. Clean the filter regularly (such as daily or weekly) according to the degree of pollution in the aquaculture water and the frequency of use of the filtering drum. For some aquaculture environments with poor water quality and more impurities, it may be necessary to clean it once a day. Avoid using sharp tools when cleaning to avoid damaging the filter.

2. Check the equipment operation status

1) Motor inspection:

Check the motor's operation regularly, including the motor's temperature, sound, and vibration. The temperature of a normally operating motor should be within a reasonable range and generally will not overheat. If the motor housing feels hot to the touch, it may be that the motor is overloaded or has poor heat dissipation.

Listen to the sound of the motor running to see if it is normal. Under normal circumstances, the motor running sound is stable, without abnormal noise or friction. If there is a harsh sound or periodic impact sound, it may mean that the internal parts of the motor are worn or foreign objects have entered.

Observe the vibration of the motor. Excessive vibration may be caused by unbalanced motor installation, impeller damage, etc. A vibration meter can be used (if conditions permit) for accurate measurement. Generally, the vibration amplitude of the motor is required to be within the range specified by the equipment.

2) Water pump inspection:

Check the inlet and outlet water pressure of the water pump. You can observe the pressure change by installing a pressure gauge on the inlet and outlet pipes. Under normal circumstances, the inlet pressure should be stable and the outlet pressure should be within the normal working pressure range of the filtering drum. If the inlet pressure is too low, the inlet pipe may be blocked; if the outlet pressure is too high or too low, the pump impeller may be damaged or air may have entered the pump.

Check the seal of the water pump to prevent water leakage. Check the seal of the water pump regularly to see if there are any water drops seeping out. Minor leaks can be solved by tightening the seal; if the leak is serious, the seal may need to be replaced.

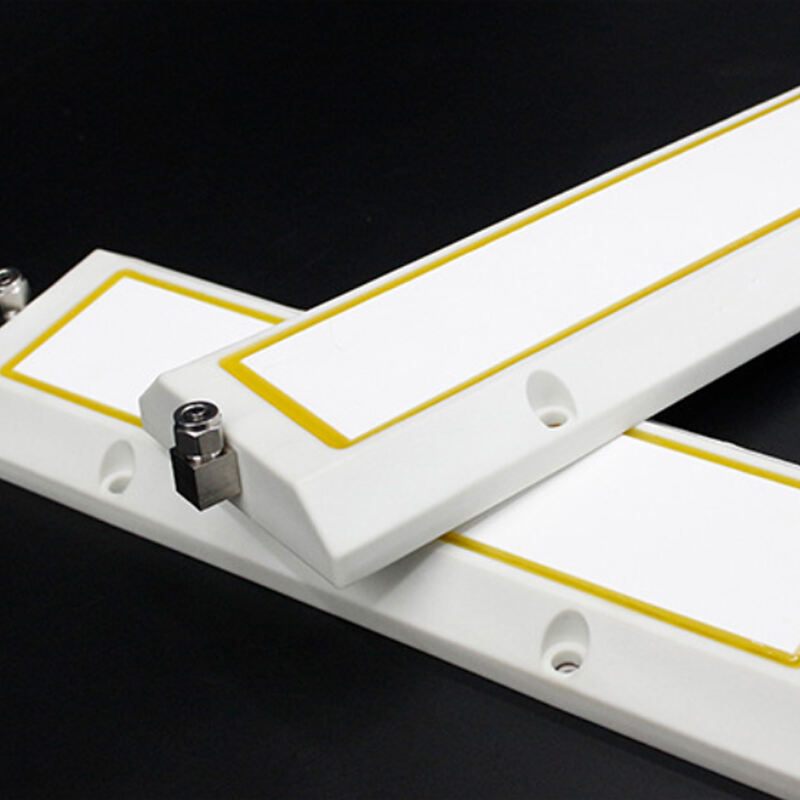

3. Backwash system maintenance

If the filtering drum is equipped with an automatic back washing system, check the operation of the back washing device regularly. Check whether the back washing valve can be opened and closed normally, and whether the back washing time interval and flushing intensity meet the requirements. The back washing parameters can be reasonably adjusted according to the actual situation of the aquaculture water body. For example, when it is found that the filter screen is blocked faster, the back washing time interval can be appropriately shortened or the flushing intensity can be increased. Check whether the back washing water source is clean and avoid using dirty water for back washing, otherwise the filter screen will be contaminated again.

4. Lubrication and tightening

1) Lubrication parts maintenance:

For parts such as bearings and gears on the filtering drum that need lubrication, add lubricating oil or grease regularly (such as once a quarter) according to the requirements of the equipment manual. Choose a suitable lubricant to ensure that it can maintain good lubrication performance in a humid breeding environment.

Before adding lubricant, clean the dirt and old lubricant on the surface of the parts, and then evenly apply or inject new lubricant. Be careful not to use too much lubricant to avoid overflow and contamination of equipment and water.

2) Fastening parts inspection:

Regularly check the bolts, nuts and other fastening parts on the filtering drum machine to prevent loosening due to equipment vibration. Use appropriate tools (such as wrenches) to check and tighten each part one by one, especially the connecting bolts of the inlet and outlet pipes, the mounting bolts of the motor and other key parts.

5. Water quality monitoring and adjustment

Monitor the water quality after being treated by the filtering drum machine regularly (such as once a week). The main monitoring indicators include turbidity, suspended matter content, dissolved oxygen, etc.

Based on the water quality monitoring results, determine whether the filtering effect of the filtering drum is normal. If it is found that the water quality indicators do not meet the aquaculture requirements, such as increased turbidity, the filtering drum may be faulty or the filtering parameters need to be adjusted. At this time, you can check whether the filter is damaged, whether it has been cleaned thoroughly, or whether the filter needs to be replaced.

At the same time, according to the water quality, the operation time and filtration speed of the filtering drum can be reasonably adjusted. For example, in the period of serious water pollution, the operation time of the filtering drum can be appropriately extended and the filtration speed can be increased to ensure good water quality.

Recommended Products

Hot News

-

The Christmas discount has arrived

2024-12-26

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20