How to choose a filtering drum machine for recirculating aquaculture?

How to choose a filtering drum machine

filtering drum is very important in recirculating aquaculture, so how to choose a filtering drum machine? When choosing a filtering drum machine for recirculating aquaculture, you need to consider the following factors:

- Filter selection

1. Filter accuracy

One of the main functions of a filtering drum is to remove total suspended particulate matter from water. The mesh size (aperture) of the filter directly affects the removal efficiency of TSS. Studies have shown that when the mesh size of the filter increases from 150 to 200, the removal rate increases rapidly, but after exceeding 200 mesh, the increase in removal rate is no longer significant. Therefore, a 200-mesh filter is the most cost-effective choice for recirculating aquaculture.

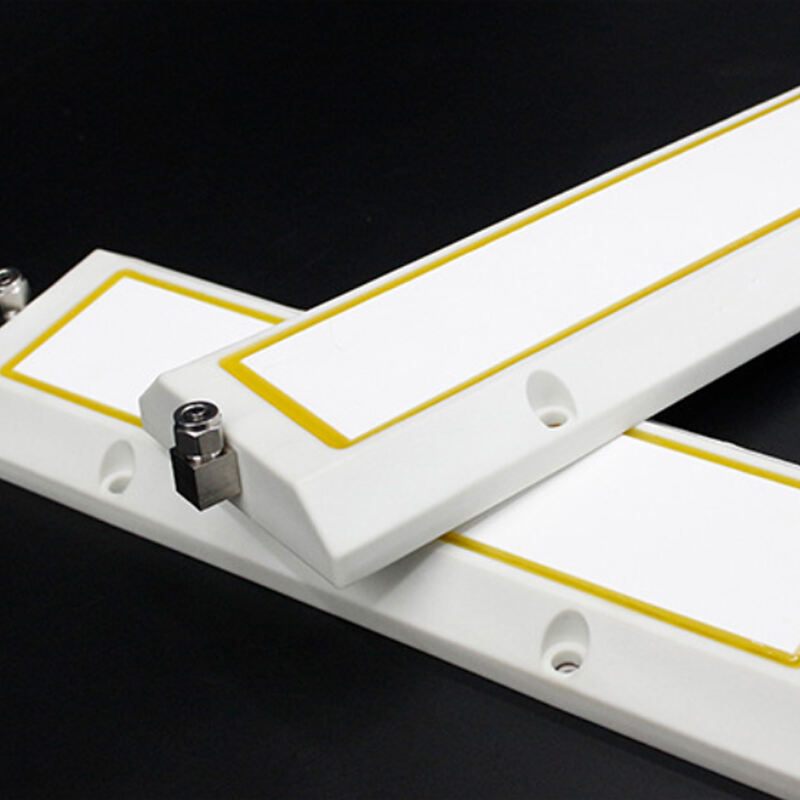

2. Filter material

1) Corrosion resistance

In a recirculating aquaculture system, the water contains various chemicals, such as disinfectants, acidic or alkaline substances produced by the decomposition of minerals and organic matter. Therefore, the filter material needs to have good corrosion resistance. Stainless steel filter (such as 304 or 316 stainless steel) is a common choice. It can resist the erosion of corrosive substances such as chloride ions in the water and is suitable for most freshwater and marine aquaculture environments.

For some special chemical environments, such as water bodies containing high concentrations of heavy metal ions or strong acids and alkalis, it may be necessary to choose special plastic filters, such as polytetrafluoroethylene (PTFE) filters, which have excellent chemical stability.

2) Mechanical strength and wear resistance

The filter needs to have sufficient mechanical strength and wear resistance during long-term water flow impact and frequent cleaning. Nylon filter and polyester fiber filter are better choices. They not only have good wear resistance, but also will not be easily deformed or damaged when subjected to certain water pressure and water flow impact.

In some large-scale, fast-flowing circulating water systems, more attention should be paid to the mechanical strength of the filter. For example, in a factory-scale circulating aquaculture workshop, the water circulation speed is high, and a high-strength filter needs to be selected to ensure its stability during long-term operation.

2. Water treatment volume

The water volume of the filtering drum is determined according to the scale of the aquaculture water body. For large industrial circulating water aquaculture farms, dozens or even hundreds of cubic meters of water may need to be processed per hour. Generally speaking, the rated water volume of the filtering drum will be indicated on the product manual of the filtering drum. Make sure that the water volume of the selected filtering drum can meet the circulation requirements of the entire aquaculture system to avoid water quality deterioration due to insufficient processing capacity. For example, for a 500 cubic meter aquaculture pond with a circulation cycle designed to be once every 2 hours, you need to choose a filtering drum that can process at least 250 cubic meters of water per hour.

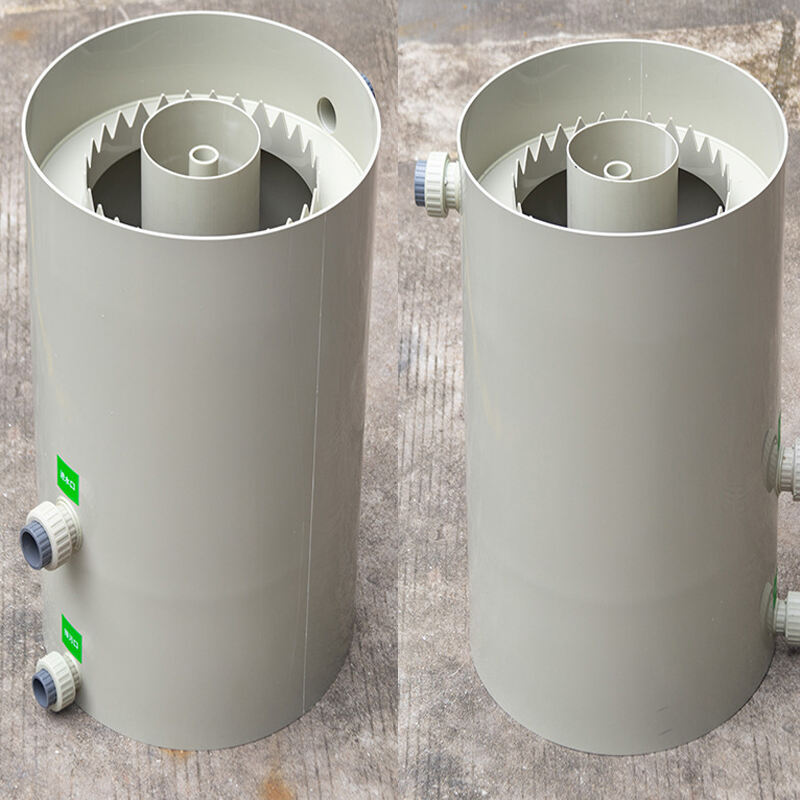

3. Aircraft Material and Structure

The main material of the filtering drum should have good corrosion resistance, because the water in the recirculating aquaculture system contains various minerals, microorganisms and chemicals. Stainless steel and PP are both ideal choices. 304 stainless steel can be selected for freshwater aquaculture, and 316 stainless steel or PP is recommended for marine aquaculture. They can resist the erosion of corrosive substances such as chloride ions in the water and extend the service life of the filtering drum.

The structure of the filtering drum should be designed to facilitate installation, maintenance and cleaning. For example, choose a filtering drum with a removable housing or filter, so that it can be easily operated when the filter is blocked or the equipment needs maintenance. Reasonable internal water flow channel design is also important to ensure that the water flows evenly through the filter and forms a stable filtering flow state on the filter surface to avoid local water flow being too fast or too slow and affecting the filtering effect.

4. Power train

The power of the filtering drum is mainly used to drive the water pump to circulate the water through the filter. It is necessary to consider whether the power of the motor is sufficient, and also pay attention to its energy consumption. Insufficient power will cause the water flow rate to be too slow, affecting the filtration efficiency; while excessive power will cause energy waste.

It is wise to choose a filtering drum with an energy-efficient motor. For example, some filtering drums with variable frequency motors can automatically adjust the motor speed according to the actual water quality and water volume required, reducing energy consumption while ensuring the filtration effect. In addition, the protection level of the motor is also very important. For humid aquaculture environments, motors with a protection level of at least IP54 should be selected to prevent water from entering the motor and causing damage.

5. Automation/Intelligence

filtering drums with a high degree of automation can greatly reduce the workload of manual operations. For example, a filtering drum with an automatic back washing function can automatically start the back washing program when the pressure difference of the filter reaches a certain threshold, flushing away impurities on the filter through reverse water flow and restoring filtering capacity.

Some high-end intelligent filtering drums can also be connected to the water quality monitoring equipment of the entire aquaculture system, automatically adjusting the filtration speed and back washing cycle according to water quality parameters (such as turbidity, suspended matter content, etc.) to achieve intelligent water quality control. The blockage of the filtering drum or the damage of the filter can be judged by the liquid level in the filtering drum cavity, and the operating status of the motor or cleaning water pump can be judged by current monitoring.

6. Brand and after-sales service

Choosing a filtering drum machine from a well-known brand can usually guarantee the quality and performance of the product. These brands have relatively strict standards in product research and development, production processes and quality control. For example, some brands that have been deeply involved in the field of aquaculture equipment for many years have products that have been verified by a large number of practical applications and have high reliability.

Good after-sales service is also a factor to consider. filtering drum machines may have various faults during use. Timely technical support and maintenance services can reduce the losses caused by equipment downtime to aquaculture production. It is necessary to understand whether the manufacturer's after-sales service network covers your own breeding area and its after-sales response time.

Recommended Products

Hot News

-

The Christmas discount has arrived

2024-12-26

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20