The functions and common problems of filtering drum machine!

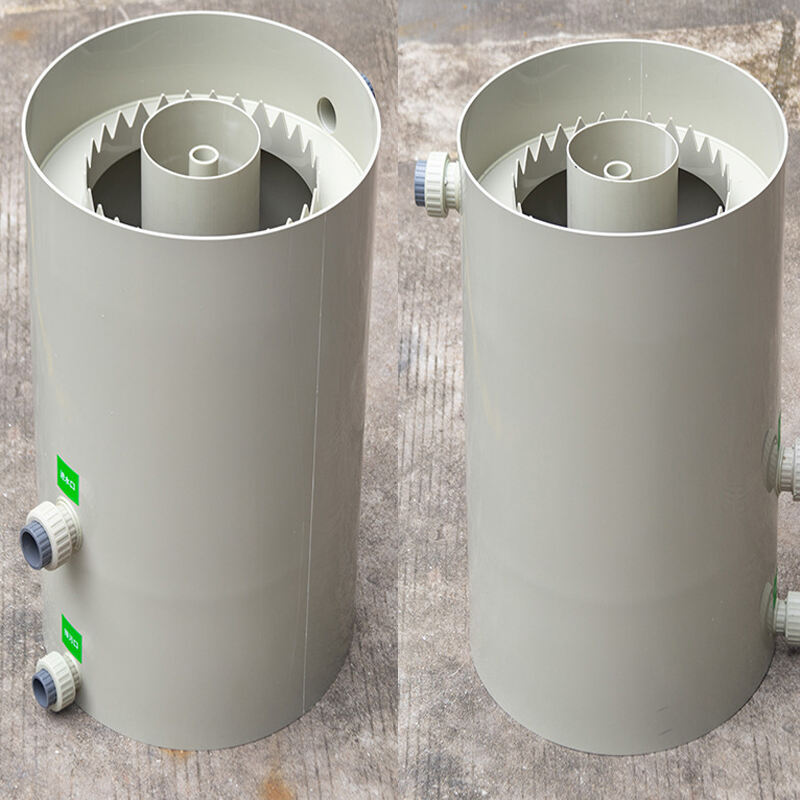

1. The role of filtering drum machine

The role of filtering drum in recirculating aquaculture systems (RAS) is multifaceted, specifically:

1. Physical filtration to remove suspended matter:

filtering drum can effectively remove suspended solids (TSS) in water, including feed residues, fish feces, dead aquatic organisms, silt, etc., and reduce the organic load in the water. Its filtration accuracy is between 100 microns and 30 microns. For example, the pore size of the common filtering drum machine filter is between 60 and 200 microns. It is like a fine sieve that blocks larger impurities outside the filter and makes the circulating water clearer. In aquaculture, if these suspended solids are not removed in time, they will decompose in the water, consume a lot of oxygen, and produce harmful substances such as ammonia nitrogen, which will affect the growth and health of farmed organisms. Taking the culture of perch as an example, there are more residual bait and feces in the water of perch culture. After using the filtering drum machine, the content of suspended solids in the water can be greatly reduced, which effectively improves the water quality and provides a relatively clean growth environment for perch.

2. Reducing the load on the biofilter

The filtering drum intercepts and removes small particles that cannot be removed by the vertical flow sedimentation device through mechanical filtration, reducing the organic load of the biological filter and providing a more suitable growth environment for nitrifying bacteria. Nitrifying bacteria require a certain amount of organic matter, but too high an organic matter content will cause the reproduction of other microorganisms, competing with nitrifying bacteria for growth space and nutrients. Nitrifying bacteria are very fragile compared to other microorganisms, and a large increase in organic matter in the water body will cause nitrifying bacteria to lose the competition with other microorganisms. Therefore, the filtering drum provides more favorable growth conditions for nitrifying bacteria by removing most of the organic matter, prolonging the service life of the biological filter material and improving the treatment efficiency of the entire system.

3. Improving the effectiveness of ultraviolet disinfection

In a recirculating aquaculture system, filtering drum machines and ultraviolet disinfection equipment usually work together. As a pre-treatment device, the filtering drum machine first removes suspended solids and larger impurities in the water, so that the subsequent ultraviolet disinfection can play a more effective role. The water filtered by the filtering drum machine has increased transparency and reduced suspended matter in the water, so that ultraviolet rays can better penetrate the water body and irradiate the microorganisms in the water, improving the disinfection efficiency. For example, in an actual recirculating aquaculture pond, the sterilization rate of ultraviolet disinfection equipment may only be 70% - 80% for water that has not been filtered by a filtering drum machine due to the large amount of suspended matter. After filtering by a filtering drum machine, the sterilization rate of the same ultraviolet disinfection equipment can be increased to 95% - 99%. At the same time, ultraviolet disinfection can kill tiny pathogens that cannot be removed by filtering drum machines, further purify the water quality, and provide a safer and healthier water environment for aquaculture organisms.

4. Improving water quality and realizing recycling of some water resources

filtering drum machines have a significant effect on reducing suspended solids (SS), chemical oxygen demand (COD) and biochemical oxygen demand (BOD) in water. The reduction of these indicators directly reflects the improvement of water quality and has a good effect on improving the transparency of water bodies. Before using filtering drum machines, circulating water may appear turbid and have low transparency due to the presence of suspended matter. After filtering by filtering drum machines, the transparency of water bodies can be significantly improved. The water filtered by filtering drum machines has significantly improved water quality and can be returned to the breeding pond for recycling. This saves water resources to a certain extent, which is of great economic and environmental significance to recirculating water aquaculture enterprises.

2. Common problems of filtering drum machine

(I) Poor filtering effect

1. Filter blockage

As the filtration process continues, impurities in the water, such as feces and feed residues, will gradually accumulate on the filter. When the filter is severely clogged, the resistance of water flowing through the filter increases, the filtration speed slows down, and some impurities cannot be effectively filtered. For example, in a circulating water system with high-density breeding, if the filter of the filtering drum is not cleaned for a long time, a large amount of organic matter will accumulate on the filter, just like setting a barrier at the entrance of the filter, making it impossible for water to pass smoothly, thereby reducing the filtration effect. At the same time, the clogging of the filter causes the liquid level in the drum cavity of the filtering drum to rise, constantly triggering back washing. The drum motor keeps turning with dozens of tons of water, wasting water and electricity, and accelerating equipment wear. Therefore, filter clogging is the most common and most harmful problem of filtering drum.

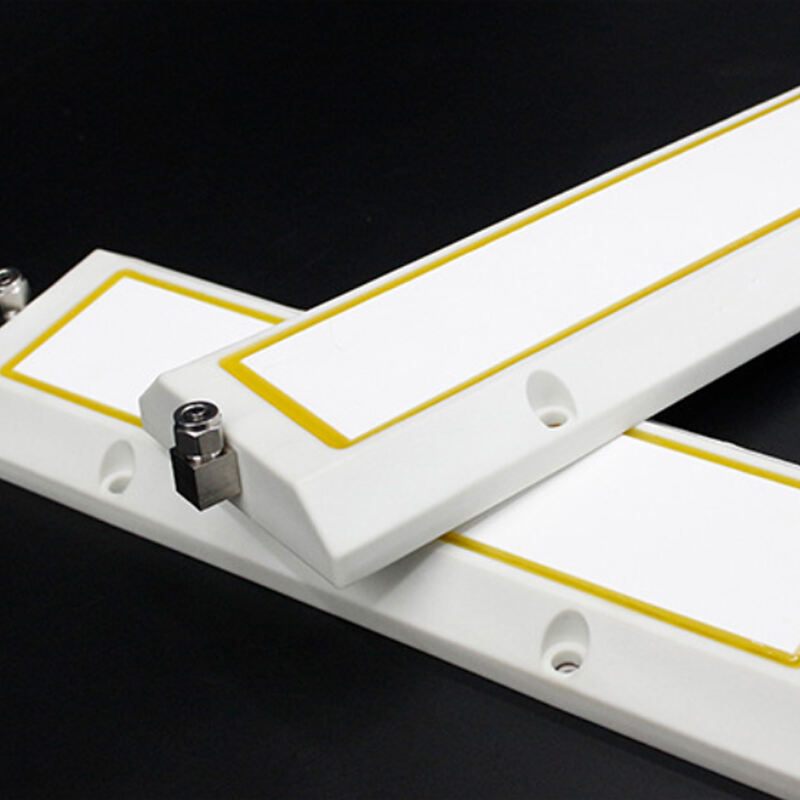

2. The filter is damaged:

During long-term use, the filter may be damaged due to the impact of water flow, frequent cleaning or contact with sharp objects. Once the filter is damaged, some larger particles that should have been filtered out will directly pass through the filtering drum machine into the aquaculture water, affecting the water quality.

(II) Backwash system failure

1. Insufficient or excessive backwash intensity

Backwash failures often manifest as insufficient or excessive backwash intensity. The backwash intensity needs to be reasonably adjusted according to the degree and type of filter blockage. If the backwash intensity is insufficient, impurities on the filter cannot be completely removed. This may be caused by a blocked duckbill or a water pump failure. It is recommended to choose a straight high-pressure nozzle instead of a spray nozzle. In addition, the water source for back washing is best connected to tap water or clean water.

If the backwash intensity is too high, the filter structure may be damaged. For example, when setting the backwash parameters, if the viscosity of impurities in the water is not taken into account, the backwash intensity may be inappropriate.

2. Automatic backwash sensor failure

In an automatic backwash system, a fault in the sensor used to detect parameters such as filter blockage degree and water level may cause the backwash to fail to start correctly. For example, the filter blockage degree sensor may not accurately detect the signal that back washing is required due to being covered by impurities, circuit damage, or aging of its own components.

3. Insufficient water pressure or air pressure

filtering drum back washing is often driven by water pressure or air pressure. Insufficient water pressure or air pressure is a common reason why back washing cannot be started. This may be caused by water supply pump or air supply pump failure, pipeline leakage, filter blockage leading to reduced water or air supply, etc.

(III) Motor failure

1. Overload

If the filter screen of the filtering drum is seriously clogged, the load of the motor will suddenly increase, requiring the motor to have a greater torque to drive the drum, thus causing overload. Long-term overload operation will cause the motor to overheat or even burn out.

2. Short circuit:

In a humid breeding environment, if the motor protection measures are not in place, water may enter the motor and cause the motor to short-circuit. Motor short-circuit can cause tripping, and in severe cases may damage key components such as the motor windings. For example, when the filtering drum machine's housing is not well sealed or the motor's waterproof level is not enough, water splashes into the motor during heavy rain or when cleaning the equipment, which can easily cause a short circuit.

Recommended Products

Hot News

-

The Christmas discount has arrived

2024-12-26

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20